Fully automated AI-powered

quality control systems

adapted to corporate requirements of

the household chemicals' producers

-

Quality control on fast production lines in the FMCG sector

The FMCG industry faces the challenges of high market saturation and numerous competitors. The level of competitiveness is largely determined by the speed of introducing new products and the product pricing.

The challenges of the FMCG industry make quality control take on a new importance. High-volume production on high-speed production lines requires modern automated quality control systems to ensure uninterrupted production and minimize downtime.

The multitude and diversity of products (increasingly advanced and diversified types of packaging and closures, diversified products with different viscosities and densities) pose new challenges to quality control. Production systems must cope with the increasing diversity and complexity of production and constant product changes.

The dynamics of the FMCG industry requires not only effective automated machine quality control systems, but also their scalability and flexibility.

-

AI-driven quality control systems to solve the challenges of the FMCG industry. Check how the systems from the Inspect 360+ series can support your production processes.

-

The future of the FMCG industry with automated vision quality control systems based on artificial intelligence

- Inspect 360+ KSM Vision seriesInspect 360+ systems take into account the specificity and complexity of the FMCG industry:

– based on deep neural networks, Inspect 360+ allows for the detection of defects that were not anticipated at the time of system implementation – given the variability and diversification of cosmetic production, this is an important advantage.

– Inspect 360+ systems ensure quick response to market and production requirements: the ability to quickly and easily adding new reference models and ‘training’ the system on an ongoing basis.

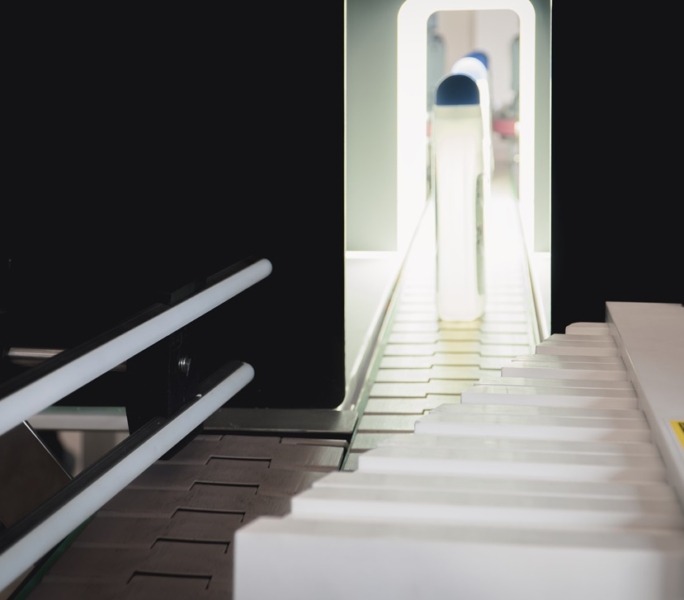

– compactness and compatibility of Inspect 360+ allows integration with the plant’s production lines – small dimensions enable installation on new and existing production lines.

– integration with the plant’s IT systems – thanks to software based on neural networks, KSM Vision systems can be adapted to corporate requirements in terms of the manufacturer’s IT systems: data exchange, management of user rights, reporting. -

KSM Vision automated vision systems

- adapted to corporate and IT requirements of the plantInspect 360+ systems cover the needs of household chemicals producers in terms of quality control throughout the entire production process.

Inspect 360+ is a comprehensive vision systems, trained for new products using neural network architecture and integration with the plant’s IT structure.

The Inspect 360+ series offers:

– Inspect 360+ LI: quality control of paper and sleeve labels and entire packaging of various types – atomizer bottles, jars, pouches, string bags, etc.; Inspect 360+ LI is fully integrated with the plant’s IT, allowing you to check the correctness of EAN, UFI, BATCH codes, label content and reporting.

– Inspect 360+ CL – a compact system for inspection of various closures, which allows for quick training for new product formats. Inspect 360+ has the option of pouring level detection.

– Inspect 360+ LI – inspection of collective packaging labels.

The machine vision systems

integrated with the IT system

of your production plant

Here are five key reasons why investing in automated quality control systems that can be integrated with the factory IT is an important investment in FMCG production:

- Higher precision and accuracy: Automated quality control systems powered by AI are able to analyze data more precisely, which allows detecting even the smallest deviations from product quality standards.

- Reduction of response time: Integration with IT allows for ongoing data transfer from the production process to the quality control system. In the event of quality problems, you can react quickly, which minimizes losses and the risk of producing defective products.

- Real-time monitoring: Automated AI-driven systems allow for real-time monitoring of product quality, enabling quick identification and elimination of quality problems.

- Scalability: Thanks to neural network architecture, Ai-driven quality control systems can easily adapt to the changing scale of production. They can be expanded and adapted to the factory’s needs as production develops.

- Data centralization: IT integration allows you to centralize data from various production processes and quality control points. This facilitates analysis, reporting and decision-making at the management level.

The conclusion is that automated quality control systems integrated with the factory’s IT help improve product quality, production efficiency and enable quick response to possible quality problems, which translates into savings and increased company competitiveness.