Fully automated quality control systems

of tablets, capsules, vials

and their packaging,

for pharmaceutical and supplement

producers

-

Automated quality control for the pharmaceutical sector

Strict legal and quality requirements related to the pharmaceutical production as well as the dynamics of this industry force pharma producers to introduce innovations into their production processes such as: automation, robotization and computerization.

The pharma industry is subject to numerous regulations – the Pharmaceutical Law Act, legal acts, production requirements (e.g. GMP – Good Manufacturing Practice), and obligations, e.g. serialization of drugs.

Quality control in pharmacy is one of the processes that can be and should be highly automated and digitized.

At KSM Vision, we combined innovative optical systems with advanced automation and machine learning using neural networks to adapt machine vision solutions to the requirements of corporate pharmaceutical companies and their IT systems in terms of: data exchange, user authorization management, reporting.

-

AI-driven quality control systems to solve the challenges of the pharmaceutical industry. Check how KSM Vision systems can support your production processes.

-

Blispect - quality control of tablets and capsules in blisters

Blispect by KSM Vision is a modern vision system based on the deep neural networks (deep learning AI) which is able to replace manual inspection in the entire production process.

Blispect significantly increases the precision and reliability of automatic production control. Thus, it meets the high expectations of the pharmaceutical industry, e.g. requirements regarding data integrity in the GMP process – our systems are equipped with the Audit Trail functionality.

Quality control procedures in pharmacy require checking each product and its packaging.

Blispect is a vision-based quality control system for medicines packed in blisters, tablets and capsules of various shapes and sizes.

Blispect system offers one software for the machine vision processes of various product formats. The friendly user interface allows you to add new product formats. Training the system for new products is fully automated and takes less than 3 minutes thanks to machine learning algorithms based on neural networks.

Blispect can be integrated with any blistering machine and rejection unit.

-

Inspect 360+ - Quality control of packaging for vaccine, syrup, medicine, and supplement manufacturers

Vision quality control systems based on artificial intelligence from the Inspect 360+ series by KSM Vision are the future of the pharmaceutical industry.

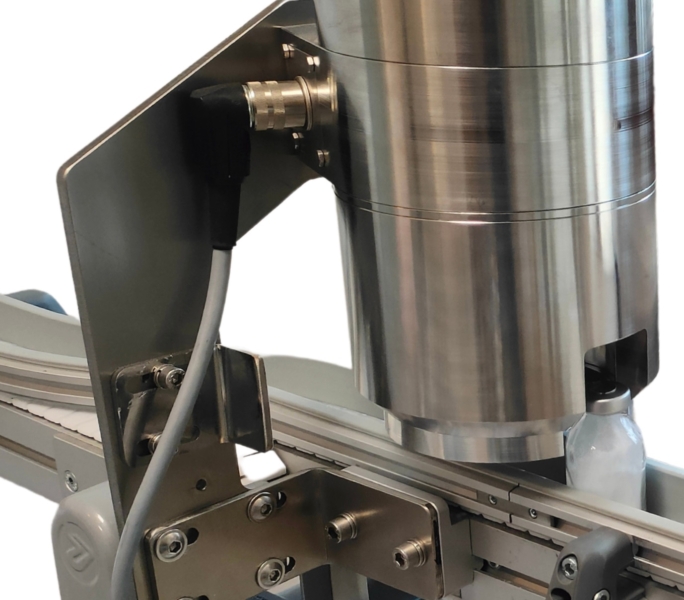

Inspect 360+ CL is an optical system for quality control of bottle and vial closures; as an option, it allows you to check the level of liquid pouring.

Inspect 360+ LI is a fully automated label inspection system that analyzes, among others, the language and correctness of the label content, its quality, but also verifies the BATCH # or expiration date.

Inspect 360+ systems stand for the right answer to the specificity and complexity of the pharmaceutical sector:

– the system ensures quick response to market and production requirements – the ability to quickly and easily adding new reference models and product formats and “train” the system on an ongoing basis.

– the compactness and compatibility of the Inspect 360+ series allows for integration with the plant’s production lines – small dimensions enable installation on new and existing production lines.

– based on deep neural networks, the system allows for the detection of defects that were not anticipated at the time of system implementation – given the variability and diversity of cosmetic production, this is an important advantage.

– integration with the plant’s IT systems – thanks to the software based on neural networks, KSM Vision systems can be adapted to corporate requirements in terms of the manufacturer’s IT systems: data exchange, user rights management, reporting.

Vision quality control systems

using artificial intelligence

for the pharmaceutical industry

Pharma production should embrace the use of AI vision systems for automated product quality control for a number of reasons:

- Accurate Defect Detection: AI systems can identify defects in tablets, capsules, vials and cartons, ensuring product safety and effectiveness.

- Automated quality control: AI-based quality control allows for quick and automatic detection of hazards, which reduces production time.

- Minimizing the risk of human errors: Eliminating errors during quality control translates into cost reduction.

- Enhancing safety: Eliminating the defects or products translates into patient safety.

- Cost reduction: Elimination of defects on the earlier stages of the production process reduces the global costs significantly.

- Solution to staffing shortages: Automated AI machine vision systems that can replace manual control, helps solving workforce problems in the labor markets.

- Regulatory compliance: AI systems are flexible. Thus they can be applied to various regulations and industry standards, which helps in compliance with legal and quality requirements.

Introducing AI-powered vision systems to control the quality of different pharma products and their packaging translates to improved product quality and patient safety.