Use of X-rays in quality control systems

One of the main advantages of X-ray inspection systems is their multitasking capability. In addition to detecting foreign bodies in products, they can be used, among other things, in measuring the weight and dimensions of workpieces, in quality control of packaging and its closures, and for monitoring the filling level of containers. What are the characteristics and how does X-ray quality control work?

How do X-ray inspection systems work?

The use of X-ray inspection on production lines is now becoming a standard in many industries. X-ray inspection systems are complementary to other systems, such as vision inspection systems. To meet the expectations of customers, our company also has them in its offer.

What are the characteristics and how does RTG quality control work? The product moving on the production line conveyor belt is x-rayed using rays. An image is created based on how far the X-ray waves can penetrate into the product. Visible spots, or dark areas, indicate that foreign bodies or other contaminants have been detected. Examples of such contaminants include glass crumbs, metal filings, scraps of plastic, rubber, seeds and others. This is an extremely dangerous phenomenon not only for potential purchasing customers, but also represents a serious cost for the company when it has to recall an entire batch of items. An additional cost is also the processing of massive incoming complaints or the possible payment of compensation.

The accidental introduction of contaminated products into the market also hits the manufacturer’s reputation, as such incidents can damage the company’s image for years to come. In addition, foreign bodies in the product can block, or damage machinery resulting in significant financial losses when the equipment has to be repaired, a new one purchased or production halted.

Is x-ray inspection safe?

The negative effects of radiation on the health of service or personnel working in the vicinity, as well as on product quality, have not been known for a long time. However, it turns out that the use of X-ray quality control is not dangerous. The radiation to which a product is subjected does not contaminate it. In the case of food products, it also does not affect their taste, color, texture or freshness.

Radiation also does not reflect on the health of workers. A full-time operator will receive a radiation dose of 2 mSv per year. This is actually a low result, compared to the approximately 2.4 mSv of radiation each of us takes in from various other sources.

X-ray inspection - is it worth it?

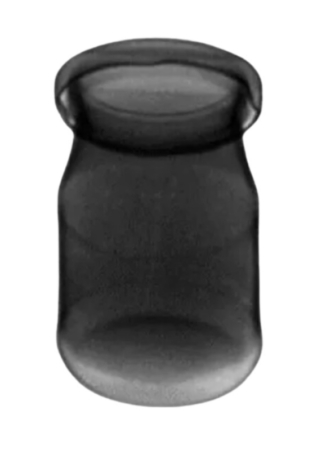

One of the main advantages of X-ray inspection systems is their multitasking capability. In addition to detecting foreign bodies in products, they can also be used, among other things, in measuring the weight and dimensions of workpieces, in quality control of packaging and its closures, and when monitoring the filling level of containers. An additional advantage is that this method does not need direct visibility between the scanner and the product. This makes it possible to test prepackaged products, among others. Like any machine, this system has some limitations. Such a system can have difficulty detecting contaminants such as hair, insects, paper, gristle and wood. This is due to the low density of these objects.

Benefits of X-ray quality control from our KSM Vision team

KSM Vision was founded in 2012, driven by the desire to implement modern analysis technologies in industry. We have extensive experience in the design and installation of vision-based quality control systems, as well as the implementation of X-ray quality control. Our inspection systems are:

- Accurate- detect foreign bodies from 0.3 mm in size

- Safe- provide non-invasive and effective inspection

- Technologically advanced- our designs use the latest foreign body detection technologies on the market

- Flexible – they enable extensive product quality control including counting, weight estimation, checking fill level and checking product leakage.

In addition, they are dedicated to different types of industries and product types, even in the most demanding ones such as food, cosmetics and medicines.

To sum up: when you choose products from our company KSM Vision, you can count on the highest quality of production and save money and time by using intelligent X-ray inspection systems.