Inspect 360+ LI RS

1st worldwide

self-learning &

auto-calibrating

inspection system

for FMCG label

quality control

- About

- Advantages

- Defects detected

- Technical Data

- Gallery

- Brochure

- Concept

Inspect 360+ LI RS system offers fully automated machine vision for packaging label quality control. The system is dedicated for the global FMCG manufacturers who face mislabeling problems when exporting products. Missing ingredients required on the product label by local law? Incorrect label language of the exported product? Missing allergens declared? The challenges due to mislabeling are more and more frequent ending with whole lots or containers of products being withdrawn from the market.

Inspect 360+ LI RS label inspection system solves these issues with cutting-edge features unique in the quality control market, such as:

- Remote Setup of the system for the new label inspection by Marketing/Quality Assurance Department of the global FMCG manufacturer (not directly on the production line by the line operators)

- Double checking of the label content during remote setup by the business departments (before it is sent to factory for production)

- Auto-Calibration of the system based upon the remotely uploaded label artwork file.

The flexibility of Inspect 360+ LI RS allows for defect detection on diverse product formats, regardless their shape or size:

- packaging possible for inspection - atomizer bottles, jars, cartons, pouches, bags, doypacks, instant bags, bigbags, trays, sachets, bottles with unusual shapes and bends

- labels - paper labels, foil sleeve labels

With an architecture based on neural networks, Inspect 360+ LI RS can eliminate manual inspection of products, increasing the efficiency of your production line.

The system is fully prepared for integration with the factory’s IT systems, in terms of user permissions, reporting, data exchange.

This flexibility enables KSM Vision to provide bespoke quality control solutions that address particular corporate challenges like no other OEM.

Inspect 360+ LI RS:

- meets the requirements of advanced production lines for fast-moving continuous packaging production

- is integrated with the IT of the production plant - thanks to the use of neural networks, the system is adapted to corporate requirements

- can handle a variety of product formats - training the system for new products takes minutes, and reformatting is fully automated

- is equipped with a user-friendly interface that allows adding new formats and offers visualization of results in graphic form

- thanks to a special illumination chamber, the system can perform effective inspection of 1.5mm text on a 2l bottle sleeve label

Inspect 360+ LI RS is a cutting-edge technology that streamlines production operations and ensures consistent quality across manufacturing sectors such as cosmetic, pharmaceutical, food and beverage, and more broadly FMCG.

Learn more about automated quality control per industry:

- quality control vision systems for manufacturers of cosmetics

- quality control vision systems for manufacturers of food and beverage

- quality control vision systems for manufacturers of pills and supplements

Check other KSM Vision's vision systems for your industry:

- machine vision for cosmetic industry by KSM Vision

- machine vision for food industry by KSM Vision

- machine vision for pharma industry by KSM Vision

Inspect 360+ LI RS label inspection system solves these issues with cutting-edge features unique in the quality control market, such as:

- Remote Setup of the system for the new label inspection by Marketing/Quality Assurance Department of the global FMCG manufacturer (not directly on the production line by the line operators)

- Double checking of the label content during remote setup by the business departments (before it is sent to factory for production)

- Auto-Calibration of the system based upon the remotely uploaded label artwork file.

The flexibility of Inspect 360+ LI RS allows for defect detection on diverse product formats, regardless their shape or size:

- packaging possible for inspection - atomizer bottles, jars, cartons, pouches, bags, doypacks, instant bags, bigbags, trays, sachets, bottles with unusual shapes and bends

- labels - paper labels, foil sleeve labels

With an architecture based on neural networks, Inspect 360+ LI RS can eliminate manual inspection of products, increasing the efficiency of your production line.

The system is fully prepared for integration with the factory’s IT systems, in terms of user permissions, reporting, data exchange.

This flexibility enables KSM Vision to provide bespoke quality control solutions that address particular corporate challenges like no other OEM.

Inspect 360+ LI RS:

- meets the requirements of advanced production lines for fast-moving continuous packaging production

- is integrated with the IT of the production plant - thanks to the use of neural networks, the system is adapted to corporate requirements

- can handle a variety of product formats - training the system for new products takes minutes, and reformatting is fully automated

- is equipped with a user-friendly interface that allows adding new formats and offers visualization of results in graphic form

- thanks to a special illumination chamber, the system can perform effective inspection of 1.5mm text on a 2l bottle sleeve label

Inspect 360+ LI RS is a cutting-edge technology that streamlines production operations and ensures consistent quality across manufacturing sectors such as cosmetic, pharmaceutical, food and beverage, and more broadly FMCG.

Learn more about automated quality control per industry:

- quality control vision systems for manufacturers of cosmetics

- quality control vision systems for manufacturers of food and beverage

- quality control vision systems for manufacturers of pills and supplements

Check other KSM Vision's vision systems for your industry:

- machine vision for cosmetic industry by KSM Vision

- machine vision for food industry by KSM Vision

- machine vision for pharma industry by KSM Vision

Advantages:

- Remote Configuration by Marketing Dept. (1st vision system worldwide with such option)

- Auto-Calibration & ‚Self-learning’ feature (1st vision system worldwide with such option)

- Quantitative and qualitative label inspection

- Traceability of all products, global defect database

- Configurable new formats and new labels (quick system training for new formats and ROI ('Region of Interest') in minutes)

- Different products and labels supported using the same software (scalable in time for new needs)

- Special illuminating chamber (no reflections, high accuracy – text of 1.5 mm is correctly read on a 2l bottle)

- Easy integration with plant IT systems for: data exchange, user rights management, reporting

Options:

- separation system (wedge conveyor)

- separation system (multi-segment rejector)

- defined trend values and alarms

- detailed reporting

What do you gain?

- Increased Operational Efficiency - reduction of waste (full product containers /product lots saved), downtimes and manual labor

- Sustainability goals met

- A guarantee of consumer safety

- Enhancement of brand reputation and trust - consistent delivery of high quality products

- Remote Configuration by Marketing Dept. (1st vision system worldwide with such option)

- Auto-Calibration & ‚Self-learning’ feature (1st vision system worldwide with such option)

- Quantitative and qualitative label inspection

- Traceability of all products, global defect database

- Configurable new formats and new labels (quick system training for new formats and ROI ('Region of Interest') in minutes)

- Different products and labels supported using the same software (scalable in time for new needs)

- Special illuminating chamber (no reflections, high accuracy – text of 1.5 mm is correctly read on a 2l bottle)

- Easy integration with plant IT systems for: data exchange, user rights management, reporting

Options:

- separation system (wedge conveyor)

- separation system (multi-segment rejector)

- defined trend values and alarms

- detailed reporting

What do you gain?

- Increased Operational Efficiency - reduction of waste (full product containers /product lots saved), downtimes and manual labor

- Sustainability goals met

- A guarantee of consumer safety

- Enhancement of brand reputation and trust - consistent delivery of high quality products

Inspect 360+ LI RS provides full automated detection of potential product label defects, including inspection and analysis of:

- presence of obligatory ingredients/allergens on the label

- BATCH, EAN, UFI codes

- label presence

- position/location of the label on the package

- inverted or upside down label

- skewing label

- peeling off

- wrinkles

- multiple labels

- unclear printing, blurred graphics, etc.

For sachets, pouches, zipper bags, "instant" meals, etc. Inspect 360+ LI RS additionally performs seal inspection:

- blurring of graphics

- product height

- tightness

- top/side seal

- cutout (e.g. pouch)

- deformations

- lack of continuity of the seal

- foreign bodies (typically small fragments of packaged food)

- presence of obligatory ingredients/allergens on the label

- BATCH, EAN, UFI codes

- label presence

- position/location of the label on the package

- inverted or upside down label

- skewing label

- peeling off

- wrinkles

- multiple labels

- unclear printing, blurred graphics, etc.

For sachets, pouches, zipper bags, "instant" meals, etc. Inspect 360+ LI RS additionally performs seal inspection:

- blurring of graphics

- product height

- tightness

- top/side seal

- cutout (e.g. pouch)

- deformations

- lack of continuity of the seal

- foreign bodies (typically small fragments of packaged food)

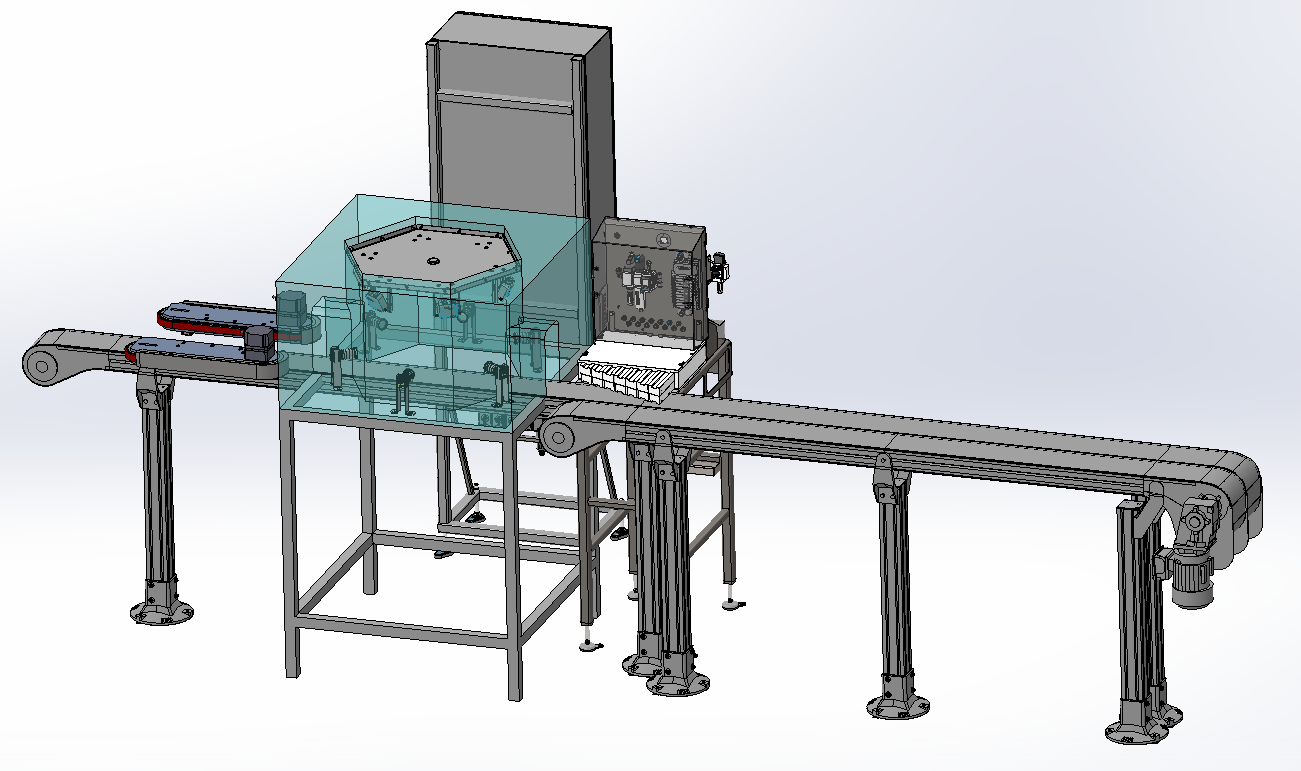

The system includes the following components:

- touch panel to control the system

- dedicated controller allowing integration into the control logic of the production line

- reject station (optional)

- set of cameras with illuminators

- machine learning software based on the deep neural networks (deep learning AI)

- special illumination chamber to protect against reflections and false rejections

Features:

- capabilities to classify defective packages

- ability to interface with production line control signals

Configurable interface and database

Based on the production specification system interface can be adjusted, including automatic system set-up with data upload by higher-order system (e.g. MES) and additional data upload by line operator. Data collected by the system can be automatically uploaded to higher-order system.

- touch panel to control the system

- dedicated controller allowing integration into the control logic of the production line

- reject station (optional)

- set of cameras with illuminators

- machine learning software based on the deep neural networks (deep learning AI)

- special illumination chamber to protect against reflections and false rejections

Features:

- capabilities to classify defective packages

- ability to interface with production line control signals

Configurable interface and database

Based on the production specification system interface can be adjusted, including automatic system set-up with data upload by higher-order system (e.g. MES) and additional data upload by line operator. Data collected by the system can be automatically uploaded to higher-order system.

Currently, quality control systems for packaging label inspection are manually configured by production line operators, leading to human errors and potential downtimes.

The challenge gets escalated by high rotation of production labor lacking related expertise and ever-changing local market regulations.

The mislabeling errors - like allergens or ingredients missing on the label, wrong label language, etc. - become more and more frequent causing operation and financial losses, and hindering zero-waste sustainability goals of FMCG exporters.

Inspect 360+ LI RS by KSM Vision solves these issues by introducing cutting-edge features automating and digitizing the label quality control process to a degree hitherto impossible to handle. What are the unique features of Inspect 360+ LI RS?

- Remote Setup of the system for the new label inspection by Marketing/Quality Assurance Department of the global FMCG manufacturer. Using the label image file (‚artwork’) sent by the Manufacturer’s Marketing or QA Dept the quality control system is configured remotely.

- Double checking of the label content during remote setup by the business departments (before it is sent to factory for production). T he Marketing/Quality Assurance Department has the possibility to define the 'Region of Interest' (ROI) on the new label that should be inspected by the Inspect 360+ LI RS quality control system.

- Auto-Calibration of the system - After uploading new artwork by Marketing/Quality Assurance Department, the system ‚self-learns’ from 30 products correctly scanned on the production line, and automatically recalibrates for the new label inspection.

Inspect 360+ LI RS ‘100% automated label quality control’ system is developed under EIT Food R&D project, in a consortium with Campden BRI Hungary (non-profit R+D+I institute) and Maspex (a leading EU food manufacturer).

Learn more about at > Automation and digitization of the food product label quality control

The challenge gets escalated by high rotation of production labor lacking related expertise and ever-changing local market regulations.

The mislabeling errors - like allergens or ingredients missing on the label, wrong label language, etc. - become more and more frequent causing operation and financial losses, and hindering zero-waste sustainability goals of FMCG exporters.

Inspect 360+ LI RS by KSM Vision solves these issues by introducing cutting-edge features automating and digitizing the label quality control process to a degree hitherto impossible to handle. What are the unique features of Inspect 360+ LI RS?

- Remote Setup of the system for the new label inspection by Marketing/Quality Assurance Department of the global FMCG manufacturer. Using the label image file (‚artwork’) sent by the Manufacturer’s Marketing or QA Dept the quality control system is configured remotely.

- Double checking of the label content during remote setup by the business departments (before it is sent to factory for production). T he Marketing/Quality Assurance Department has the possibility to define the 'Region of Interest' (ROI) on the new label that should be inspected by the Inspect 360+ LI RS quality control system.

- Auto-Calibration of the system - After uploading new artwork by Marketing/Quality Assurance Department, the system ‚self-learns’ from 30 products correctly scanned on the production line, and automatically recalibrates for the new label inspection.

Inspect 360+ LI RS ‘100% automated label quality control’ system is developed under EIT Food R&D project, in a consortium with Campden BRI Hungary (non-profit R+D+I institute) and Maspex (a leading EU food manufacturer).

Learn more about at > Automation and digitization of the food product label quality control

They trust our know-how: