Uncompromising

precision and reliability

AI-powered

optical quality control systems

We combine machine learning algorithms with customized hardware,

creating the most comprehensive automated optical quality control solutions

Our systems are dedicated to the corporate manufacturing needs in the industries such as FMCG (pharma, food, beverage, cosmetics, chemicals) – as well as woodworking and construction.

By equipping our systems with machine learning algorithms based on the neural networks (deep learning AI), we are able to eliminate manual quality inspection, and replace it with automated machine quality control processes.

The KSM Vision systems collect and analyze real data from production lines, basing statistics on large collections and AI data mining algorithms. Our systems provide manufactures with in-depth production statistics, global defect database, and alerts on potential problems with machinery, empowering global manufacturers with higher precision and accuracy of production.

KSM Vision Solutions

-

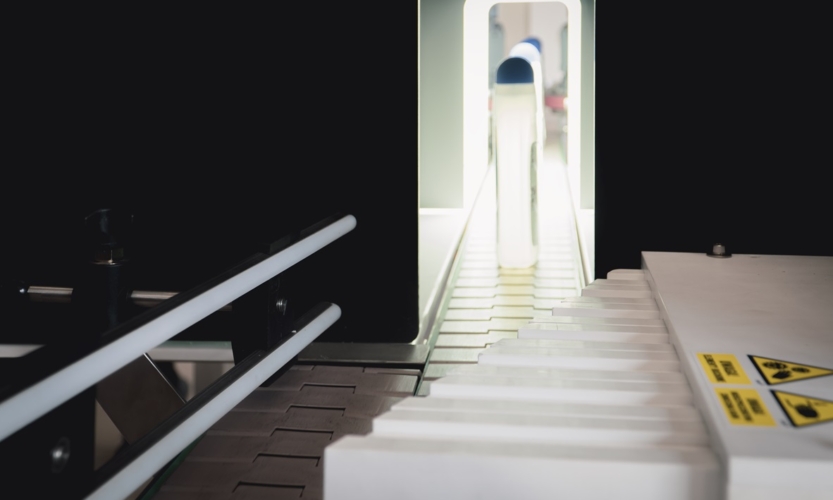

Label Inspection - Inspect 360+ LI

Label Inspection - Inspect 360+ LI

With an architecture based on neural networks, Inspect 360+ LI can eliminate manual inspection of products, increasing the efficiency of your production line inspections. KSM Vision systems are tailored to meet corporate requirements, in terms of manufacturing plant IT systems: data exchange, user rights management, reporting.

The flexibility of Inspect 360+ LI allows you to apply the system for diverse formats:

- packaging - atomizer bottles, cartons, pouches, "instant" bags, sachets, bottles with unusual shapes and bends

- labels - paper labels, foil sleeve labelsIf you're a manufacturer in the FMCG market, check out what Inspect 360+ LI does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Inspect 360+ LI by KSM Vision -

Packaging Closure Control - Inspect 360+ CL

Packaging Closure Control - Inspect 360+ CL

The innovative Inspect 360+ CL optical system is an advanced automation with software using machine learning. By using neural networks, the system can eliminate manual inspection of products, increasing inspection efficiency. It is customized to meet corporate requirements for manufacturing plant IT systems: data exchange, user rights management, reporting.

The system meets the requirements of advanced high-speed continuous motion (high-volume production) production lines for filling and sealing vials, bottles and other similar containers.

If you're a food, chemical or pharmaceutical manufacturer, check out what Inspect 360+ CL does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Inspect 360+ CL by KSM Vision -

Empty Can Inspection - Inspect 360+ DSC

Empty Can Inspection - Inspect 360+ DSC

The innovative Inspect 360+ DSC optical system is an advanced automation with software using machine learning. Using neural networks, the system can eliminate manual inspection of food or chemical products in sealed cans, increasing inspection efficiency.

The system is customized to meet corporate requirements for manufacturing plant IT systems: data exchange, user rights management, reporting.

The system meets GUPH hygiene standards and HACCP guidelines, as well as the requirements of advanced production lines with fast continuous motion (high-volume production).

If you are a manufacturer in the food or chemical industry (e.g., paints for lacquers), check out what Inspect 360+ DSC does differently from other machine vision solutions and learn how it can help optimize your production lines.

Get to know Inspect 360+ DSC by KSM Vision -

Pharma & Supplement Inspection - Blispect

Pharma & Supplement Inspection - Blispect

A vision-based system for quality control of pills and capsules in blisters. The system can be adapted to any blistering machines and operation logic, including the rejection station.

Quality control procedures in pharmaceuticals require inspection of each product and its packaging.

Blispect, with its neural network-based architecture, completely replaces manual product inspection, increasing the efficiency of production line inspection.

The system meets the pharmaceutical industry's GAMP-5 requirements and features Audit Trail.

Find out what Blispect does differently from other machine vision solutions and how it can help optimize your production lines.

Get to know Blispect by KSM Vision -

Wood Inspection - Woodspect

Wood Inspection - Woodspect

Woodspect is a state-of-the-art, fully automated machine vision system based on neural networks, for manufacturers and factories of furniture, wood flooring, windows and facades.

The flexibility of the Woodspect systems allows it to be applied to the needs of different types of wood-based products, including but not limited to:

- laths, boards

- boards (including glued laminated wood)

- plywood

- floor panelsThe system is customized to meet corporate requirements for manufacturing plant IT systems: data exchange, user rights management, reporting.

If you're a manufacturer of furniture, windows, facades, flooring, or wood processing more broadly, check out what Woodspect does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Woodspect by KSM Vision -

Hollow and Paving Block Inspection - Brickspect

Hollow and Paving Block Inspection - Brickspect

Brickspect is a fully automated vision-based material defect detection system for building material manufacturers. Due to the limited availability of human resources, more and more processes (previously unprofitable) are being automated in the construction industry.

Using the vision cameras and machine learning algorithms used in Brickspect, we efficiently carry out the processes of detecting and removing defects in bricks or blocks.

If you are a building materials manufacturer, check out what Brickspect does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Brickspect by KSM Vision

Label Inspection - Inspect 360+ LI

With an architecture based on neural networks, Inspect 360+ LI can eliminate manual inspection of products, increasing the efficiency of your production line inspections. KSM Vision systems are tailored to meet corporate requirements, in terms of manufacturing plant IT systems: data exchange, user rights management, reporting.

The flexibility of Inspect 360+ LI allows you to apply the system for diverse formats:

- packaging - atomizer bottles, cartons, pouches, "instant" bags, sachets, bottles with unusual shapes and bends

- labels - paper labels, foil sleeve labels

If you're a manufacturer in the FMCG market, check out what Inspect 360+ LI does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Inspect 360+ LI by KSM Vision

Packaging Closure Control - Inspect 360+ CL

The innovative Inspect 360+ CL optical system is an advanced automation with software using machine learning. By using neural networks, the system can eliminate manual inspection of products, increasing inspection efficiency. It is customized to meet corporate requirements for manufacturing plant IT systems: data exchange, user rights management, reporting.

The system meets the requirements of advanced high-speed continuous motion (high-volume production) production lines for filling and sealing vials, bottles and other similar containers.

If you're a food, chemical or pharmaceutical manufacturer, check out what Inspect 360+ CL does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Inspect 360+ CL by KSM Vision

Empty Can Inspection - Inspect 360+ DSC

The innovative Inspect 360+ DSC optical system is an advanced automation with software using machine learning. Using neural networks, the system can eliminate manual inspection of food or chemical products in sealed cans, increasing inspection efficiency.

The system is customized to meet corporate requirements for manufacturing plant IT systems: data exchange, user rights management, reporting.

The system meets GUPH hygiene standards and HACCP guidelines, as well as the requirements of advanced production lines with fast continuous motion (high-volume production).

If you are a manufacturer in the food or chemical industry (e.g., paints for lacquers), check out what Inspect 360+ DSC does differently from other machine vision solutions and learn how it can help optimize your production lines.

Get to know Inspect 360+ DSC by KSM Vision

Pharma & Supplement Inspection - Blispect

A vision-based system for quality control of pills and capsules in blisters. The system can be adapted to any blistering machines and operation logic, including the rejection station.

Quality control procedures in pharmaceuticals require inspection of each product and its packaging.

Blispect, with its neural network-based architecture, completely replaces manual product inspection, increasing the efficiency of production line inspection.

The system meets the pharmaceutical industry's GAMP-5 requirements and features Audit Trail.

Find out what Blispect does differently from other machine vision solutions and how it can help optimize your production lines.

Get to know Blispect by KSM Vision

Wood Inspection - Woodspect

Woodspect is a state-of-the-art, fully automated machine vision system based on neural networks, for manufacturers and factories of furniture, wood flooring, windows and facades.

The flexibility of the Woodspect systems allows it to be applied to the needs of different types of wood-based products, including but not limited to:

- laths, boards

- boards (including glued laminated wood)

- plywood

- floor panels

The system is customized to meet corporate requirements for manufacturing plant IT systems: data exchange, user rights management, reporting.

If you're a manufacturer of furniture, windows, facades, flooring, or wood processing more broadly, check out what Woodspect does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Woodspect by KSM Vision

Hollow and Paving Block Inspection - Brickspect

Brickspect is a fully automated vision-based material defect detection system for building material manufacturers. Due to the limited availability of human resources, more and more processes (previously unprofitable) are being automated in the construction industry.

Using the vision cameras and machine learning algorithms used in Brickspect, we efficiently carry out the processes of detecting and removing defects in bricks or blocks.

If you are a building materials manufacturer, check out what Brickspect does differently than other machine vision solutions and learn how it can help optimize your production lines.

Get to know Brickspect by KSM Vision

They trust our know-how:

The most innovative

AI-driven inspection systems

empowering your production

Modern automated quality control systems for industry are designed not only to detect potential production defects, but also to collect, review, compare and analyze all data on the production process.

Classifying defects over a longer period of time helps optimize the production process. This happens, for example, when a lot of defects of a certain type can be linked to a failure, or suboptimal parameters of any of the production machines.

At KSM Vision, we combine innovative optical systems with advanced automation, electronics and dedicated software, based on artificial intelligence methods and neural networks.

As a result, our applications are able to provide customers with online feedback on their production or potential machine and production problems. This includes automatic archiving, reporting, notifications and alerts, and based on big data analysis and data mining algorithms.

Explore the most innovative vision-based quality control solution.