Automatic quality control in construction industry

Automated quality control in the construction industry is undoubtedly the future of construction. Reducing material costs is a matter of remaining competitive in the market. Vision-based quality control systems are one of the most effective ways of detecting defects in construction materials, allowing them to be quickly rectified, and therefore reducing costs during production itself as well as those associated with possible complaints about defective products or even entire batches.

Quality control in construction field

Construction industry is a dynamically growing sector. Year to year there are more investments, which leads to ever growing competition. To continue on with your business in the construction field you need to overcome many challenges. There are less and less construction professionals on the market, there’s an ongoing struggle to gain potential customers and contrahents. The prices go up all the time which makes materials more and more costly. It is on the companies to search for innovations that will keep them in the game. One of the new technologies that make the difference are vision and automatic quality control systems.

KSM Vision quality control systems

Vision quality control systems are extremely efficient in detecting faults in construction materials, which then allows for quick fix and lesser production costs. Better fault detecting minimizes complaints and returns caused by damaged products and even entire lots of them. Implementation of automatic quality control systems, which is much more exact than the human eye, minimizes the risk of faulty items going to clients.

Vision quality control systems are extremely efficient in detecting faults in construction materials, which then allows for quick fix and lesser production costs. Better fault detecting minimizes complaints and returns caused by damaged products and even entire lots of them. Implementation of automatic quality control systems, which is much more exact than the human eye, minimizes the risk of faulty items going to clients.

What and how do we control? Wooden boards quality control

KSM Vision has been involved in the construction industry from the very beginning. At first we equipped our clients with solutions for measuring shape, displacements and deformations construction elements.

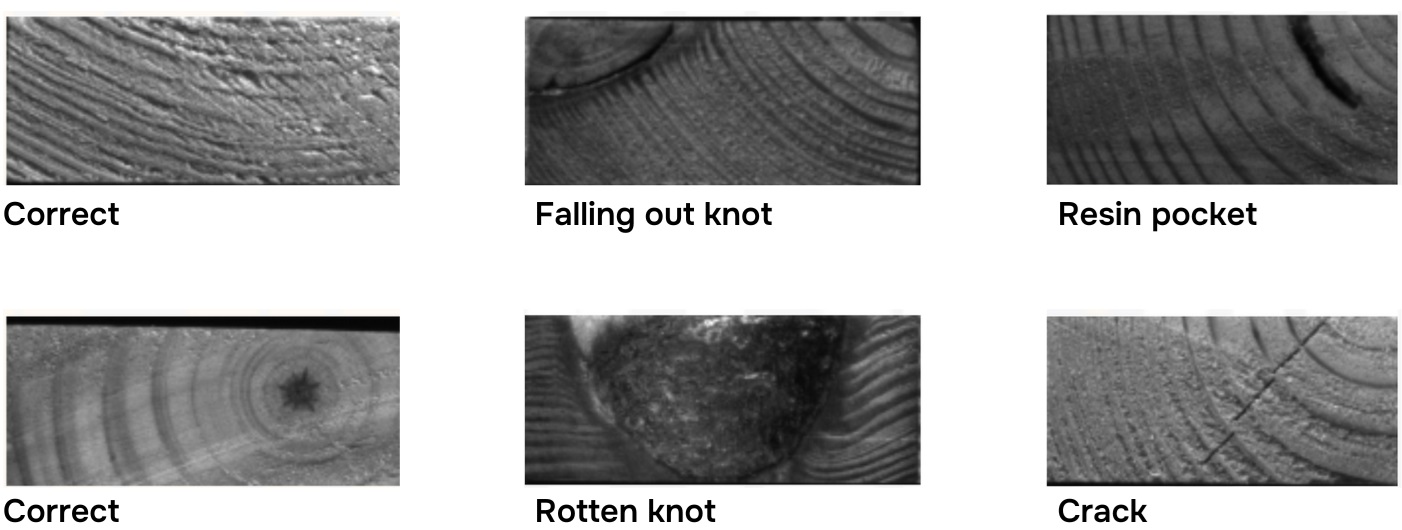

Machine vision systems, which are solutions based on a camera that scans the product in scope of 360 degrees, detect any departure in the structure of the controlled item, as compared to the ideal template. This kind of equipment has been implemented in furniture production and in plants where wooden floors are made. Quality control systems used in wooden boards production can be divided into those that detect faults in raw boards and those that offer precise geometrical measurement in 360 degrees. Faults in raw boards can be resin pockets, rotten knots, mechanical damages. This sort of control is useful in eliminating faults from points of junction, as well as in automation of the products outer layer repair. Precise geometrical measurement in 360 degrees allows one to measure the boards surface very exactly, after they’ve been mechanically processed. This sort of control system can be used to detect the volume of losses which helps in the final filling procedure.

Both systems are based on machine vision and neural networks which enhances production efficiency. The algorithm has an effectiveness ratio of about 95%, with a minimal percentage of products eliminated from the production line.

Examples of wood board defects:

What and how do we control? Pavement quality control

The control system that we named Brickspect allows to ensure the perfect form of the cobblestones. The appliance checks the produced elements’ height which helps to control even unusual and specific designs. The algorithms used in the product’s dimensions inspection base upon the height measurement and detection of the cobblestones’ top surface faults. The system automatically finds all cracks, discolourations, decrements, faulty dimensions and others. The aforementioned algorithms allow for collecting, browsing and analyzing all data on the production process.

Examples of defects in paving blocks:

User-friendly software

In our vision quality control systems, we combine innovative optics with advanced automation, electronics and dedicated software based on artificial intelligence methods and neural networks. Intuitive software allows analysis of data collected by the system. Thanks to the architecture based on deep neural networks of KSM Vision systems, our solutions have the ability to “learn” new product formats (capturing defects against a predefined “ideal product”), so training the system for new products takes up to a few minutes.