Vision quality control – how does it work?

On the technical side, a machine vision system consists of a sensor that acquires information, an illuminator, a lens, as well as a data acquisition device and the software that enables data processing. Such a system forms the most efficient image processing system based on machine vision.

What is a vision system?

A vision system is the most powerful image processing system based on machine vision. The machine vision system is a kind of “human sense of sight,” converting, like the human eye, images into information. The eyeballs are, in machine vision, specialized cameras that capture images, and the brain is the computer and software that interprets those images accordingly. Vision-based quality control is based on examining products against an ideal standard. The cameras scan the products and pick up deviations from the standard. A machine, like a human, has to learn certain things. By scanning products and collecting information about them in databases, it uses its “experience” and knowledge stored in computer memory to identify non-ideal products. Vision systems use the capabilities of cameras to capture physical characteristics of objects for measurement and inspection. Based on a learned pattern, they automatically pick up product with irregularities and eliminate it from the production line.

Despite the many similarities between the vision system and the human body, there is one major difference between the two. The vision system, unlike the human brain, will not lose concentration or get tired. This is especially important when the production line is high speed and running for long periods of time. The human eye is sometimes unreliable and cannot cope with such accurate and careful observation. Vision systems, despite the use of advanced technology, are universal. No new system is developed for each industry, but existing ones are adapted to the specific line and product specifications.

What does a vision system consist of?

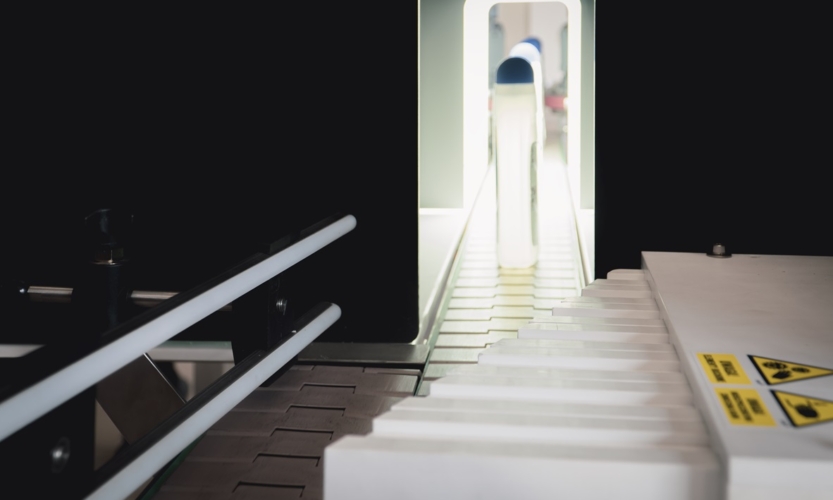

On the technical side, a vision system consists of a sensor that takes in information, an illuminator, a lens, as well as a data acquisition device and the software that enables data processing.

First, the main component of a vision system is the camera system including the lens. There are different types of them: image cameras – are used in scanning the image of the whole object or features, line cameras – used on moving production lines, and 3D cameras – showing a three-dimensional image of the product.

Lenses also can be divided into several basic types: fixed-focus lenses (the most popular), zoom lenses – used in robotics, telecentric lenses – used for precise dimensional analysis, and pericentric lenses – which allow simultaneous observation of the front and side surfaces of the lens.

Lighting used in vision systems has been completely dominated by LED lighting. This is economical and, of course, environmentally friendly, as they provide great savings. They are available in a variety of light colors – so they can be appropriately matched to the production line. The types of lighting using LEDs by vision systems are: front illuminators, back illuminators, ring illuminators, shadowless illuminators, coaxial illuminators, linear illuminators, spot illuminators, and hyperspectral illuminators also called multispectral illuminators.

Vision-based quality control systems have many advantages. They streamline the work of production lines, are a safe and effective solution ensuring high precision and efficiency. Thanks to them, the company has a chance to optimize costs and eliminate to a minimum the number of defective products, which allows to avoid possible complaints of goods or even entire batches.

Vision systems from KSM Vision

At KSM Vision, we implement vision systems, starting from production processes to logistics processes. For many years, we have been installing these systems in distribution centers, warehouses and sorting centers in various industries: food, pharmaceutical, cosmetics and construction. By using the services of our company, you can count on comprehensive service by thoroughly familiarizing yourself with the needs that the system is to meet, analyzing the production process, programming specific algorithms, selecting components, conducting tests and, as a result, assembling the finished system. We cooperate with leading producers of the highest quality components and, combined with our knowledge and experience, you receive the highest quality solutions.