Quality control for pharmaceutical industry – Medicofarma

The industry’s specific nature and the regulations on drug manufacturing translate into a very strict quality control which, considering the multitude and variety of products, is a challenge in itself. Frequent format changes (blister size, arrangement of blister cavities, colours, shapes and dimensions of capsules/tablets) are the main challenge about creating the new quality control system in the pharmaceutical industry. The solution is the BLISPECT system by KSM Vision.

Medicofarma

Medicofarma a Polish pharmaceutical manufacturer specializing in contract manufacturing of dietary supplements, medical devices, and medicinal products. The company’s clients include both key Polish companies and international pharmaceutical corporations. Medicofarma has decided to implement BLISPECT vision system by KSM Vision. Why?

The inspection using BLISPECT involves:

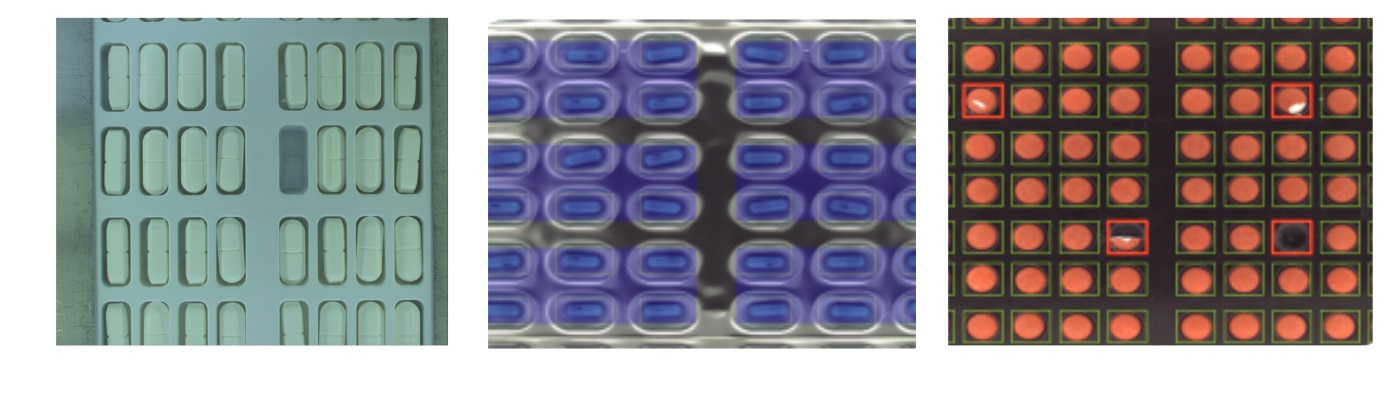

- inspection of tablets and capsules in blister packs

- bicolour capsules and printed capsules

Challenges and suggested solutions for quality control

The industry’s specific nature and the regulations on drug manufacturing translate into a very strict quality control which, considering the multitude and variety of products, is a challenge in itself. Frequent format changes (blister size, arrangement of blister cavities, colours, shapes and dimensions of capsules/tablets) were the main challenge about creating the new quality control system –conversion had to be easy and fast so as not to delay production.

What is more, the Customer expected full integration with the blistering machine and maintaining its existing functions. We met that need by integrating our vision system (Blispect) with the CAM blistering machine, keeping its work at full capacity.

Client's benefits, or why did Medicofarma choose KSM Vision quality control systems based on machine learning?

- We used our own image analysis solution based on neural networks, allowing the system to be taught within a minute by showing only photos of the correct capsules. The system can be “taught” regardless of the format of capsules/tablets.

- Thanks to the method of feature extraction using neural networks, the system can handle bicolour capsules and printed capsules.

- Detection of defects the size of 15% of the tablet/capsule surface.

- The system sensitivity is controlled by only one parameter: “tolerance”, which differentiates between good and bad capsules/tablets.

- That approach allowed us to reduce the time needed for line conversion, while maintaining the accuracy of data analysis.

- At the same time, the system is really easy to use, which translates into quicker introduction and training process of new operators, which in turn reduces downtime in production.

- Compared to traditional solutions, our system has far fewer electronic components and uses less space, because we installed a new illuminator and replaced two video cameras with a single camera, connecting an original controller that communicates the blistering machine controller with a Blispect system computer. It means that the camera is triggered at the right moment, information about the visual analysis result is collected and the result is sent to the rejectors.

More about vision systems in pharma industry