Types of scanners and cameras in automated vision quality control systems

Automated quality control systems use a variety of equipment to monitor and evaluate product quality. Check out the solutions in use. Get a free consultation with KSM Vision engineers for verification to find out which solution will work best for your industry.

- Types of equipment used in automated quality control systems

- Vision quality control devices use

- Devices using scanning and measuring technologies

- Devices using spectroscopy and chemical analysis technologies

- Microscopic quality control equipment

- Devices based on electrochemical and electrophysical technologies

- Other specialized quality control equipment

- Selecting a device for a quality control system

- Get a free consultation on selecting a quality control device for your application with a KSM Vision engineer

Choosing the right solution for use in a quality control system is critical to its efficiency and effectiveness. The choice of a particular device depends primarily on the following aspects:

- the type of materials produced and the specifics of the production process,

- industry requirements and standards governing product quality in a given field,

- speed of operation (with regard to line performance in particular),

- ability to accurately measure key product parameters,

- ability to integrate the device into existing production systems,

- ease of operation and maintenance

Also important is the cost of purchasing and maintaining the device, which must be balanced with the expected economic benefits of improved product quality. The selection of the right device should be carefully considered and based on a solid analysis of the needs and technical capabilities of the manufacturing company.

The variety of devices used in vision-based quality control systems is large. Compare possible solutions below.

Types of equipment used in automated quality control systems

Devices used in automated quality control systems can be grouped into several categories depending on their applications and the technologies they use:

- Vision-based quality control devices:

- Industrial cameras

- 3D scanners

- Thermal imaging scanners

- Optical scanners with autofluorescence

- Optical scanners with confocal detection

- Devices using scanning and measuring technologies:

- Ultrasonic scanners

- X-ray scanners

- Neutron scanners

- Gamma-ray scanners

- Electromagnetic scanners

- Devices using spectroscopy and chemical analysis technologies:

- Spectroscopic scanners

- Mass spectroscopy scanners

- Laser ionization mass spectrometry scanners

- Mass spectrometry scanners with plasma ionization

Mass spectrometry scanners with electron ionization

- Microscopic quality control equipment:

- Electron microscopy scanners

- Scanners using scanning tunneling microscopy technology

- Scanners using atomic force microscopy technology

- Scanners using AFM microscopy technology

- Scanners using STM microscopy technology

- Devices based on electrochemical and electrophysical technologies:

- Electrochemical scanners

- Magnetic scanners

- Electrophoretic scanners

- Microwave scanners

- Other specialized quality control equipment:

- Acoustic scanners

- Plasma scanners

- Dynamic phase scanners

- Isotope scanners

These categories help to understand the variety of equipment used in quality control systems and their applications in various industries and manufacturing processes.

Vision quality control devices use

Vision quality control devices use:

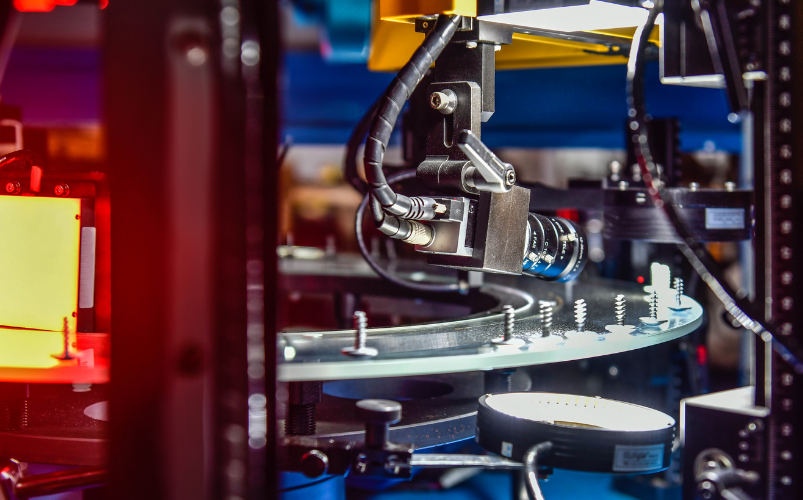

- Industrial cameras: Industrial cameras are an essential tool in automated quality control systems. Their high resolution allows accurate visual inspection of products, identification of defects and monitoring of production processes. The high resolution of industrial cameras allows accurate visual inspection of products, identification of defects and monitoring of production processes. They can quickly identify defects such as scratches, imperfections or color inhomogeneities. Thanks to laser triangulation technology, these systems can accurately measure the dimensions and shape of products, identify geometric defects and surface irregularities.

- 3D scanners: 3D scanners can generate three-dimensional models of objects, which is extremely useful for analyzing the shape and dimensions of products. This makes it possible to quickly detect outliers and surface irregularities. 3D scanners are extremely useful in industries requiring precise analysis of shape and dimensions, such as aerospace and automotive. They also allow the generation of CAD models that can be used for further design processes.

- Thermal scanners: Thermal imaging scanners can evaluate the temperature of products and identify areas of abnormal temperature, which can indicate potential quality problems, such as improper welds or overheating.

- Optical scanners with autofluorescence: They use the phenomenon of autofluorescence to identify changes in the structure of materials, which can indicate the presence of defects.

- Optical scanners with confocal detection: Allow precise analysis of the structure of materials at the microscopic level by measuring reflected and scattered light.

Devices using scanning and measuring technologies

Among devices using scanning and measuring technologies, we distinguish:

- Ultrasonic scanners: Ultrasonic scanners are commonly used to detect cracks, voids and other internal defects in materials. Ultrasonic scanners are used to non-invasively probe the internal structure of materials such as metals and composites, enabling the detection of structural defects at deeper levels. Their effectiveness in examining the structure of materials makes them indispensable in the aerospace, metallurgy and composite materials industries.

- X-ray scanners: X-ray scanners enable the penetration of materials, making it possible to visualize their internal structure and identify hidden defects such as cracks or inclusions. They are used in medicine, the automotive industry and in quality control of metal products.

- Neutron scanners: neutron scanners are used to penetrate even very dense materials, which is essential for quality analysis of metallurgical products and ceramic materials. Neutron scanners are used in cases where high-density materials, such as metallurgical or ceramic materials, need to be x-rayed, enabling precise analysis of their internal structure.

- Gamma-ray scanners: Skillfully penetrate high-density materials, enabling the detection of internal defects.

- Electromagnetic scanners: They use electromagnetic waves to analyze the properties of materials, making it possible to assess their quality and homogeneity.

Devices using spectroscopy and chemical analysis technologies

Devices using spectroscopy and chemical analysis technologies are:

- Spectroscopic scanners: They allow spectral analysis of materials to identify chemicals and assess their chemical composition, which is important in the pharmaceutical, food and chemical industries.

- Mass spectroscopy scanners: These scanners allow accurate analysis of the chemical composition of samples by measuring the molecular weight. They are widely used in scientific research and in quality control of various materials and substances.

- Laser ionization mass spectrometry scanners: Using laser radiation, they make it possible to precisely analyze the chemical composition of samples, which is crucial for identifying unknown substances and analyzing product quality.

Microscopic quality control equipment

Microscopic quality control equipment:

- Electron microscopic scanners: These scanners enable analysis of the surface structure and internal microstructure of materials at the microscopic level. Thanks to their high resolution, the microstructure of samples can be accurately assessed, which is essential in many fields such as biological sciences, materials science and engineering.

- Scanners using scanning tunneling microscopy technology: These scanners make it possible to analyze the structure of materials at the atomic level by measuring the tunneling current between the probe blades and the surface under study. They are used in nanotechnology research and in the production of electronic microelements.

- Scanners using atomic force microscopy technology: These devices make it possible to study the structure of materials at the nanometer level by measuring the forces interacting between the probe and the surface under study. They are useful for analyzing surface topography and studying the mechanical properties of materials.

- Scanners using AFM microscopy technology: AFM (Atomic Force Microscopy) scanners allow the structure and surface properties of materials to be studied at the atomic level. They are used in nanotechnology research, materials science and material surface analysis.

- Scanners using STM microscopy technology: Scanning Tunneling Microscopy (STM) scanners allow imaging the atomic structure of the surface of materials and analyzing their electrical properties at the atomic level. They are used in nanotechnology research and surface physics.

Devices based on electrochemical and electrophysical technologies

Devices based on electrochemical and electrophysical technologies:

- Electrochemical scanners: These scanners are used to evaluate the chemical composition and electrochemical properties of materials by measuring electrochemical currents and potentials. They are used in corrosion analysis, battery and fuel cell testing, and medical diagnostics.

- Magnetic scanners: They use magnetic fields to analyze the magnetic properties of materials, making it possible to detect structural defects and assess the homogeneity of magnetic materials. They are used in metallurgy, electronics, and magnetic materials research.

- Electrophoretic scanners: They allow the separation and analysis of the chemical composition of samples based on their movement in an electric field. They are used in DNA analysis, protein research, and quality control of pharmaceutical and food products.

- Microwave scanners: These devices use microwave waves to analyze the chemical composition and dielectric properties of materials, which is important in quality control of dielectric materials, textiles and food products.

Other specialized quality control equipment

Other specialized quality control equipment includes:

- Acoustic scanners: They use sound waves to assess the uniformity of materials and detect cracks, inclusions and other structural defects. They are used in the metallurgical and construction industries, as well as in medical diagnostics.

- Plasma scanners: They analyze the chemical composition of product surfaces by generating plasma and analyzing light emission. They are used in analyzing the surface of materials, identifying impurities and evaluating the chemical composition of samples.

- Dynamic phase scanners: They help analyze the phase changes of materials over time, enabling the identification of structural instabilities. They are used in the study of materials with changing phase structures and in monitoring phase transition processes.

- Isotope scanners: They use isotopes to mark and track substances in samples, enabling precise analysis of chemical composition and localization of impurities. They are used in biomedical and geochemical research and in environmental quality control.

Selecting a device for a quality control system

The device used as a quality control scanner must be selected each time for a specific application for several important reasons:

- Application requirements: Each application may require specific features and technical capabilities of the device, such as resolution, measurement range, scanning speed or accuracy. Therefore, it is important to match the device to the specific requirements of the inspection process.

- Material characteristics: Different materials have different physical and chemical characteristics, which may require different measurement technologies and techniques. For example, metallic materials can be examined with X-ray scanners, while organic materials may be more suitable for analysis with spectroscopic scanners.

- Visual complexity: Some products may be more visually complex than others, which may require more advanced vision or microscopic technologies to accurately analyze their features and structure.

- Sample size and shape: Different equipment can be optimized for different sample sizes and shapes. For example, X-ray scanners may be more suitable for analyzing large and massive products, while electron microscopes can be used to examine microscopic details.

- Expected results: Ultimately, the instrument must be matched to the expected results and quality control objectives. Depending on whether the goal is to detect structural defects, analyze chemical composition or perform geometric evaluation, choosing the right device is crucial to achieving the desired results.

Therefore, the proper selection of an instrument for a specific application is crucial to the effectiveness of the quality control process, ensuring precision, reliability and repeatability of measurements.

Get a free consultation on selecting a quality control device for your application with a KSM Vision engineer

At KSM Vision, we are specialists in vision systems and automation. We combine innovative optical systems with advanced automation and plant IT. Thanks to

use of neural networks in our vision systems, we are able to replace manual inspection of products, increasing the efficiency of inspection (the system does not get tired and does not go on

redundancies). Our systems are adapted to corporate requirements, in terms of plant IT systems: data exchange, user rights management, reporting.

KSM Vision systems are dedicated to industries such as pharmaceutical, FMCG, timber and construction. Combined with data processing based on artificial intelligence, the use of CCTV cameras, triangulation and X-ray scanners in hardware proves to be the most effective and at the same time financially beneficial in our clients’ industries.