Inspect 360+ LI

Fully-automated

and flexible IT system

for quality control

of paper and sleeve labels

on diverse packaging formats

- About

- Advantages

- Defects detected

- Technical Data

- Gallery

- Brochure

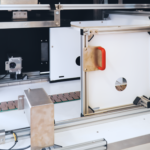

Inspect 360+ LI is a fully automated label inspection solutions that can be integrated with your manufacturing plant IT systems.

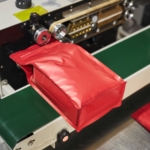

The flexibility of Inspect 360+ LI allows you to apply the system for diverse formats:

- packaging - atomizer bottles, cartons, pouches, bags, doypacks, instant bags, bigbags, trays, sachets, bottles with unusual shapes and bends

- labels - paper labels, foil sleeve labels

With an architecture based on neural networks, Inspect 360+ LI can eliminate manual inspection of products, increasing the efficiency of your production line.

KSM Vision systems are tailored to meet corporate requirements, in terms of manufacturing plant IT systems: data exchange, user rights management, reporting.

See also > 1st worldwide vision system for label quality control with auto-calibration feature

Inspect360+ LI is turnkey, its unquestionable advantage is the ability to customize the system to the client's requirements and the specifics of the plant's production (the ability to integrate with existing production line infrastructure, processes and plant IT systems, including data exchange, user rights management, comprehensive reporting). Our engineers integrate KSM Vision's proprietary software based on a flexible neural network architecture with custom hardware, tailoring the vision solution to the plant's infrastructure and processes, as well as the specifics of the client's products / defects.

This flexibility enables KSM Vision to provide bespoke quality control solutions that address particular corporate challenges like no other OEM.

Inspect 360+ LI:

- meets the requirements of advanced production lines for fast-moving continuous packaging production

- is integrated with the IT of the production plant - thanks to the use of neural networks, the system is adapted to corporate requirements

- can handle a variety of product formats - training the system for new products takes minutes, and reformatting is fully automated

- is equipped with a user-friendly interface that allows adding new formats and offers visualization of results in graphic form

- thanks to a special illumination chamber, the system can perform effective inspection of 1.5mm text on a 2l bottle sleeve label

Inspect 360+ LI is a cutting-edge technology that streamlines production operations and ensures consistent quality across manufacturing sectors such as cosmetic, pharmaceutical, food, and more broadly FMCG.

Learn more about automated quality control per industry:

- quality control vision systems for manufacturers of cosmetics

- quality control vision systems for manufacturers of food and beverage

- quality control vision systems for manufacturers of pills and supplements

Check other KSM Vision's vision systems for your industry:

- machine vision for cosmetic industry by KSM Vision

- machine vision for food industry by KSM Vision

- machine vision for pharma industry by KSM Vision

The flexibility of Inspect 360+ LI allows you to apply the system for diverse formats:

- packaging - atomizer bottles, cartons, pouches, bags, doypacks, instant bags, bigbags, trays, sachets, bottles with unusual shapes and bends

- labels - paper labels, foil sleeve labels

With an architecture based on neural networks, Inspect 360+ LI can eliminate manual inspection of products, increasing the efficiency of your production line.

KSM Vision systems are tailored to meet corporate requirements, in terms of manufacturing plant IT systems: data exchange, user rights management, reporting.

See also > 1st worldwide vision system for label quality control with auto-calibration feature

Inspect360+ LI is turnkey, its unquestionable advantage is the ability to customize the system to the client's requirements and the specifics of the plant's production (the ability to integrate with existing production line infrastructure, processes and plant IT systems, including data exchange, user rights management, comprehensive reporting). Our engineers integrate KSM Vision's proprietary software based on a flexible neural network architecture with custom hardware, tailoring the vision solution to the plant's infrastructure and processes, as well as the specifics of the client's products / defects.

This flexibility enables KSM Vision to provide bespoke quality control solutions that address particular corporate challenges like no other OEM.

Inspect 360+ LI:

- meets the requirements of advanced production lines for fast-moving continuous packaging production

- is integrated with the IT of the production plant - thanks to the use of neural networks, the system is adapted to corporate requirements

- can handle a variety of product formats - training the system for new products takes minutes, and reformatting is fully automated

- is equipped with a user-friendly interface that allows adding new formats and offers visualization of results in graphic form

- thanks to a special illumination chamber, the system can perform effective inspection of 1.5mm text on a 2l bottle sleeve label

Inspect 360+ LI is a cutting-edge technology that streamlines production operations and ensures consistent quality across manufacturing sectors such as cosmetic, pharmaceutical, food, and more broadly FMCG.

Learn more about automated quality control per industry:

- quality control vision systems for manufacturers of cosmetics

- quality control vision systems for manufacturers of food and beverage

- quality control vision systems for manufacturers of pills and supplements

Check other KSM Vision's vision systems for your industry:

- machine vision for cosmetic industry by KSM Vision

- machine vision for food industry by KSM Vision

- machine vision for pharma industry by KSM Vision

Advantages:

- 100% control over production, so you can be sure that only error-free products of the highest quality come off your production line

- immediate rejection of defective products from your production line

- traceability of all products - powerful statistical functions give you in-depth insight into the performance of your lines

- advanced lighting technology to avoid reflections and false rejects

- centralized qualitative and quantitative product control

- user-friendly interface to quickly add products and create a new order (in visual form)

- system training for new products takes minutes

- non-contact, non-invasive, fully automatic control

- integration with plant IT systems for: data exchange, user rights management, reporting

- small footprint for integration into new and existing production lines

Options:

- separation system (wedge conveyor)

- separation system (multi-segment rejector)

- defined trend values and alarms

- detailed reporting

What do you gain?

- A guarantee of consumer safety

- solving labor shortages by introducing automated machine vision based on artificial intelligence in place of manual inspection

- enhancement of brand reputation and trust - consistent delivery of high quality products

- avoiding problems and costs in the downstream process (return of a packing slip, whole batch, container, etc.)

- 100% control over production, so you can be sure that only error-free products of the highest quality come off your production line

- immediate rejection of defective products from your production line

- traceability of all products - powerful statistical functions give you in-depth insight into the performance of your lines

- advanced lighting technology to avoid reflections and false rejects

- centralized qualitative and quantitative product control

- user-friendly interface to quickly add products and create a new order (in visual form)

- system training for new products takes minutes

- non-contact, non-invasive, fully automatic control

- integration with plant IT systems for: data exchange, user rights management, reporting

- small footprint for integration into new and existing production lines

Options:

- separation system (wedge conveyor)

- separation system (multi-segment rejector)

- defined trend values and alarms

- detailed reporting

What do you gain?

- A guarantee of consumer safety

- solving labor shortages by introducing automated machine vision based on artificial intelligence in place of manual inspection

- enhancement of brand reputation and trust - consistent delivery of high quality products

- avoiding problems and costs in the downstream process (return of a packing slip, whole batch, container, etc.)

Inspect 360+ LI provides full automated detection of potential label defects, including inspection and analysis of:

- BATCH, EAN, UFI codes

- label presence

- position/location of the label on the package

- inverted or upside down label

- skewing label

- peeling off

- wrinkles

- multiple labels

- unclear printing, blurred graphics, etc.

For sachets, pouches, zipper bags, "instant" meals, etc. Inspect 360+ LI additionally performs seal inspection:

- blurring of graphics

- product height

- tightness

- top/side seal

- cutout (e.g. pouch)

- deformations

- lack of continuity of the seal

- foreign matter (typically small fragments of packaged food)

- BATCH, EAN, UFI codes

- label presence

- position/location of the label on the package

- inverted or upside down label

- skewing label

- peeling off

- wrinkles

- multiple labels

- unclear printing, blurred graphics, etc.

For sachets, pouches, zipper bags, "instant" meals, etc. Inspect 360+ LI additionally performs seal inspection:

- blurring of graphics

- product height

- tightness

- top/side seal

- cutout (e.g. pouch)

- deformations

- lack of continuity of the seal

- foreign matter (typically small fragments of packaged food)

The system includes the following components:

- touch panel to control the system

- dedicated controller allowing integration into the control logic of the production line

- reject station (optional)

- set of cameras with illuminators

- machine learning software using OCR based on the deep neural networks (deep learning AI)

- special illumination chamber to protect against reflections and false rejections

Features:

- capabilities to classify defective packages

- ability to interface with production line control signals

Configurable interface and database

Based on the production specification system interface can be adjusted, including automatic system set-up with data upload by higher-order system (e.g. MES) and additional data upload by line operator. Data collected by the system can be automatically uploaded to higher-order system.

- touch panel to control the system

- dedicated controller allowing integration into the control logic of the production line

- reject station (optional)

- set of cameras with illuminators

- machine learning software using OCR based on the deep neural networks (deep learning AI)

- special illumination chamber to protect against reflections and false rejections

Features:

- capabilities to classify defective packages

- ability to interface with production line control signals

Configurable interface and database

Based on the production specification system interface can be adjusted, including automatic system set-up with data upload by higher-order system (e.g. MES) and additional data upload by line operator. Data collected by the system can be automatically uploaded to higher-order system.

They trust our know-how: